Overview

YWB no shaft liquid pump for at -85℃ ~ 350℃ conditions, long-term transport any medium acids, oxidizers and corrosive media, widely used in chemical, petroleum, pharmaceutical, pesticide, electronics, electricity, electroplating, metallurgy, fire protection, environmental protection, national defense, rare earth smelting and other industries. Its deepest liquid up to 8 meters, use of time is ten times the number of ships under the long axis of the liquid pump, installation is very easy to use, to overcome the original single-stage single-suction sump pump during transportation and installation of shaft run easily bent and deformed ( shaft length equal to the submerged depth), bearing easily damaged, difficult to repair sleeve shortcomings.

YWB no shaft liquid pump is based on the majority of the chemical industry user requirements and design of new products, the use of external mixing type pump self-priming structure, except for the first start for the first time are required to fill the pump body pump solution, after the frequent start without perfusion diversion or pumping vacuum, easy to operate, safe and easy. Mechanical seals and domestic joint manufacturing company by the British Grand packing, reasonable structure, reliable performance, easy maintenance, energy conservation, is the ideal civilization plant construction equipment, effectively solve the long axis of easy to bend and leak.

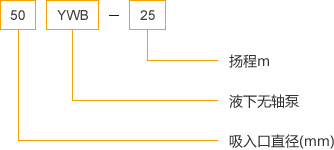

YWB no shaft liquid pump production, manufacture and acceptance of non-shaft pump products, strict compliance with the relevant standards and Taiwan and Taiwan detection, the record of unknown origin, in order to ensure the quality of products. The products were used F46, UHMWPE ultra-high polyethylene Xi River, 1Cr18Ni9Ti, 1Cr18Ni12Mo2Ti, 0Cr18Ni12Mo2Ti, Japanese standard SUS321, Japanese standard SUS304, Japan Standard SUS304L, 316 American Standard, American Standard 316L, CD4MCu, K alloy, Monel alloy, Hastelloy B alloy, Ti alloy and various cast steel, cast iron, copper, aluminum and other materials. A full range of 5 models 10 specifications, head: 10 ~ 25m, flow rate: 3.6 ~ 400m³/h.